The global semiconductor manufacturing equipment sector remains firmly dominated by the United States and Japan, with both nations controlling critical technologies that underpin the production of advanced microchips. From etching systems to precision materials, their technological edge is so significant that many of these tools are subject to strict export controls, reflecting their strategic importance in modern electronics and global supply chains.

Global Semiconductor Equipment Landscape: U.S.-Japan Dominance and Technological Barriers

The global semiconductor manufacturing equipment sector remains firmly dominated by the United States and Japan, with both nations controlling critical technologies that underpin the production of advanced microchips. From etching systems to precision materials, their technological edge is so significant that many of these tools are subject to strict export controls, reflecting their strategic importance in modern electronics and global supply chains.

Source: Images from the Internet, if there is any infringement, please contact the removal of

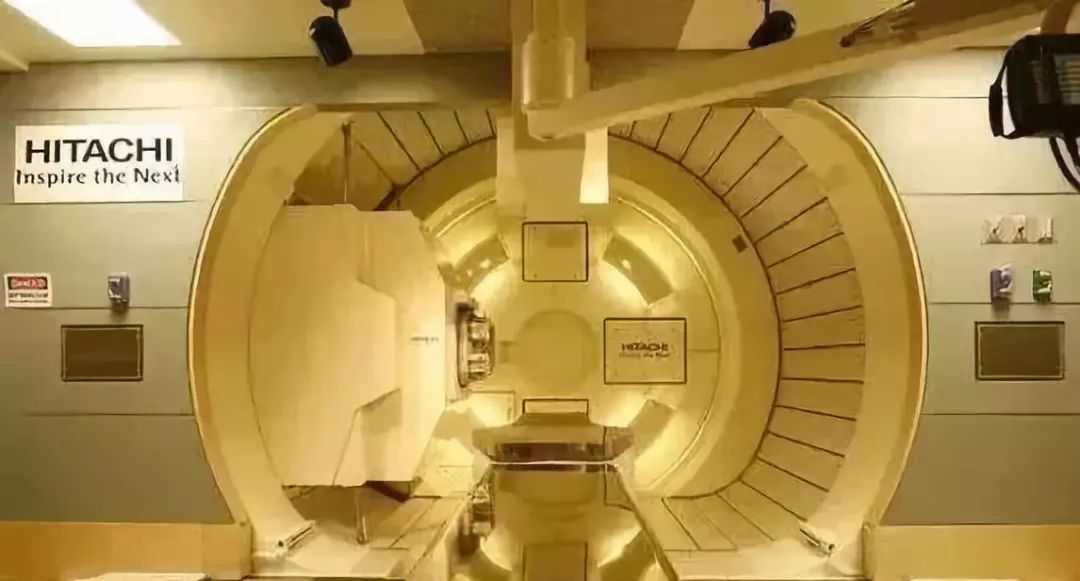

Japanese companies lead in several high-precision segments. Hitachi stands at the forefront of etching equipment, which is crucial for sculpting intricate patterns onto silicon wafers. The company’s machines enable nanometer-scale precision, a key requirement for advanced logic and memory chips. Meanwhile, Japanese materials giants like Toray and Teijin produce carbon fibers and ultra-precise components used in semiconductor manufacturing infrastructure. Hitachi also excels in grating engraving machines, capable of achieving an astounding 10,000 lines per millimeter—a level of precision vital for calibrating optical systems in lithography tools. While ASML (Netherlands) dominates extreme ultraviolet (EUV) lithography, Japanese firms like Nikon and Canon hold significant shares in older-generation lithography systems, and their expertise in precision optics remains unmatched.

The U.S. asserts its influence through companies like Applied Materials, Lam Research, and KLA, which collectively control 40% of the top 10 global semiconductor equipment manufacturers. American firms specialize in deposition, ion implantation, and inspection technologies, essential for building multi-layer chip structures and ensuring quality control. Together, U.S. and Japanese companies account for over 90% of the global market for front-end semiconductor equipment, which is used in the earliest stages of chip fabrication. This duopoly not only shapes the economics of the industry but also creates significant barriers to entry for emerging competitors, as mastering these technologies requires decades of R&D investment and industrial know-how.

The strict export controls on these tools—particularly those critical for producing advanced nodes (e.g., below 14nm)—highlight their geopolitical significance. As semiconductor technology drives innovation in AI, 5G, and defense systems, the U.S.-Japan dominance in equipment and materials underscores their roles as custodians of a sector that powers the modern world. While nations like South Korea and China have made strides in chip design and manufacturing, the reliance on U.S.-Japanese equipment and materials remains a fundamental challenge for global semiconductor sovereignty.